The entire team at Towmaster recognizes how big of an investment purchasing a trailer can be. Reliable trailers are integral to the success of our customers as it safely transports their equipment and allows them to get to and from job sites every single day.

That’s why we designed our trailers to protect our customers’ investment and equipment. There are several ways we ensure our trailers are up to the task– one of them is galvanizing our trailers.

What is Galvanizing?

Galvanizing is a process that was created to protect steel and iron from rust, corrosion, and general degradation. This process is used across industries and helps ensure longer life cycles, lower repair costs, and stronger long-term ROI. Without additional protections, steel will rust when exposed to the elements over a period of time.

Depending on the environment where our customers work, rust and corrosion can happen well before they are ready to retire the trailer. Galvanizing provides a protective zinc coating that ensures the long-term stability and safety of our steel trailers.

How Does Galvanizing Work?

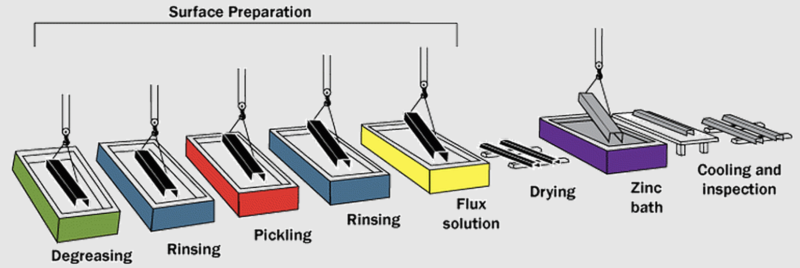

Galvanizing is a straightforward process that produces amazing results. First, steel parts are cleaned in a degreasing solution. Once it’s free of debris, the steel is “pickled” in a vat of diluted hot sulfuric acid. The steel is then fluxed in an aqueous solution (typically zinc-ammonium chloride) that prepares the steel surfaces by applying a saline layer that helps to promote the bonding of iron and zinc.

After the flux, the steel is galvanized through immersion in a vat of molten zinc. Once the steel is safe to touch, each piece is inspected for consistency and complete coating. Now you have a galvanized steel component!

What Are The Benefits of Galvanizing?

Increased Corrosion Resistance

According to the team at Crossroads Galvanizing the “Time to First Maintenance”, or TFM, is defined as the appearance of rust on only 5% of a galvanized steel surface. The TFM is reached at different times depending on the conditions of the environment.

- TFM for standard galvanized steel in an industrial environment is 72 to 73 years. Examples of an industrial environment include Newark, Atlanta, and Houston.

- TFM for standard galvanized steel in a tropical marine environment is 75 to 78 years. Examples of a tropical marine environment include Miami and Mazatlan.

- TFM for standard galvanized steel in a temperate marine environment is 86 years. Examples of temperate marine environments are Seattle and Charleston, South Carolina.

- TFM for standard galvanized steel in a suburban environment is 97 years. Examples of a suburban environment include Minneapolis and Orlando.

- TFM for standard galvanized steel in a rural environment is over 100 years. Examples of a rural environment include Fargo, North Dakota, and Las Cruces, New Mexico.

Long Lasting Material

Galvanized steel is well protected, and therefore can last through decades of rigorous use. Very little maintenance is required over a long period of time, saving our customers money and stress.

Lower Initial Costs

The galvanizing process has a lower initial cost than other treated steel materials. Once the process is complete, galvanized steel is ready to use right away. No additional surface preparations are required, saving labor and material costs that get passed on to the customer.

Stay Protected

Towmaster is an industry-leading truck and trailer equipment manufacturer, upfitter, and distributor. We offer an unparalleled trailer warranty because we are proud to stand by the build of our equipment. We invest in the success of our customers and want to ensure their investment will be protected through years of use.