Our entire team recognizes how big of an investment purchasing a trailer can be. Reliable trailers are integral to the success of our customers as it safely transports their equipment and allows them to get to and from job sites every single day.

At Towmaster we try to build trust and value into each and every one of our trailers. There are a few ways we do this– including offering galvanized steel, using American made parts and a team of expert engineers, welders, assemblers and more. Another way we build value into our products is through a process called cold forming.

What Is Cold Forming?

Cold forming is a method used to shape steel without the use of thermal processing. At room temperature, or very close to, steel can be rolled, pressed, stamped or bent into the desired shape and size for beams, joists, columns, studs and other components.

The cold forming process is used across several industries for many different applications. Cold formed steel has been used to build bridges, vehicle bodies, living facilities and in our case, our trailer’s Ii-beams.

How Does The Cold Forming Process Work?

Cold forming is a fast, consistent and less costly process that results in strong components. Steel bar stock is put under extreme pressure from a die to be shaped into a usable structure. Once the metal is compressed, it can be bent, stamped and pressed into shape for whatever application is needed.

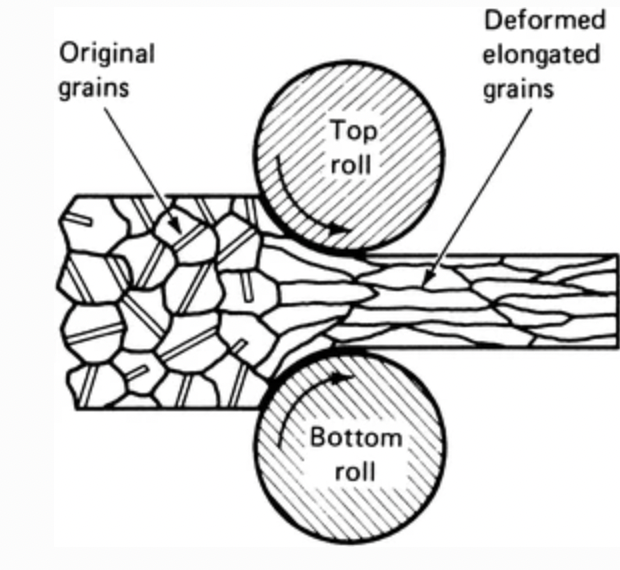

Metal components all have a grain which has a crystalline structure that is developed after molten metal cools. Within each grain, atoms form a lattice shape with neighboring atoms. When metal is cold formed the shape is permanently changed because the pressure “dislocates” or “slips” this structure. These slips allow the shape of the metal to be manipulated.

When metal is manipulated by heat instead of pressure, those “dislocated” grains can move. That movement limits the strength of the metal. Cold forming creates elongated grains that gather and compile, limiting its movement and resulting in increased tensile strength.

Advantages of Cold Forming

There are a lot of advantages cold forming offers, both for the manufacturer and the customer.

Does Not Require Heating

With no heating involved, cold forming allows for a safer environment for manufacturers and also decreases energy cost.

Strong Results

Those elongated and stacked grains result in an incredibly strong and resilient product.

Better Surface Finish

The cold forming process seldom requires secondary operations to improve the surface. The process itself results in an attractive and long lasting surface.

More Control

Steel compression through rolling, pressing, stamping or bending allows the operator to manipulate carefully and precisely.

Less Waste

The process of cold forming moves and manipulates the metal material, instead of removing areas, resulting in less scrap waste.

Faster Process

Cold forming is a quick and efficient process that can be repeated dozens of times a day.

Invest In The Best

Towmaster is an industry-leading truck and trailer equipment manufacturer, upfitter, and distributor. We offer an unparalleled trailer warranty because we are proud to stand by the build of our equipment. We invest in the success of our customers and want to ensure their investment will be protected through years of use.